卡迪斯跨楼层仓储解决方案

Kardex Remstar Multi-Level Storage Solution

高度自动化性能

Highly automated performance power

当必须建立新的系统,以提高仓储能力和订单分拣能力并减少其复杂性时,卡迪斯研发的跨楼层仓储提供了最佳解决方案。Shutttle XP 系统连接公司不同的区域,加速了处理流程,建造标准高达30米。

When new storage and order picking capacity has to be created with

little complexity, Multi-Level Storage from Kardex Remstar is the ideal

solution. The Shuttle XP system links various company areas, accelerates

processes, and can be built up to 30 meters high as standard.

目前的市场驱动力和市场趋势 -- 如快速增长的电子商务,越来越复杂的服务,更快的交货时间--是公司面临的巨大挑战。因此,必须对生产系统和仓储物流系统加以优化,以降低成本、提高生产率、增加灵活性。随着流程的复杂度不断提高,高效的仓储,以及快速、完整、可靠的货物检索和分配已成为成功的关键因素。这需要人力资源的优化利用和高性能的仓储技术,可通过现代化方式实现。考虑到货物种类的持续增长和越来越快的交货时间,货物的快速存取必不可少,目的是提高订单分拣性能并尽可能减少差错。

Current market drivers and market trends – such as rapidly growing

ecomerce, ever more complex services, and faster delivery times –

represent big challenges for companies. Production systems and storage

logistics must be optimized to cut costs, improve productivity, and

increase flexibility.When process complexity is constantly increasing,

efficient storage and fast, completed, and reliable retrieval and

distribution of goods are critical success factors that require optimal

use of human resources, but also high-performance storage technology,

which is achievable through modernization. In view of the permanently

growing range of goods and ever faster delivery times, quick access to

the goods is also essential, for higher order picking performance with

as few errors as possible.

高灵活性、高密度、仓储容量大。

High flexibility and density with large storage volume

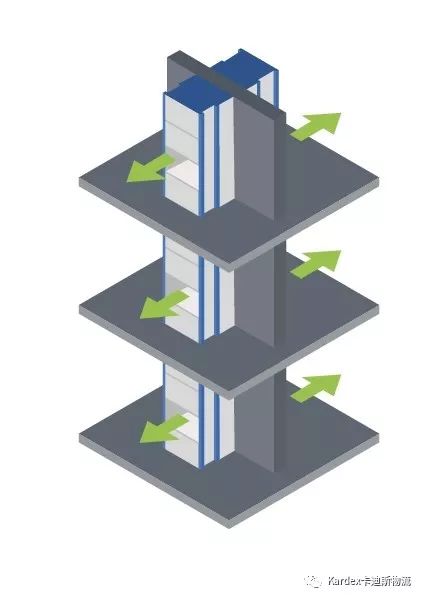

高性能、灵活、高效的仓储系统,如跨楼层仓储,对于应对这些挑战发挥着关键作用。卡迪斯设计的这类系统具有一系列的显著优势,它只需要很小的占地面积,但因其高度上的优势,所以仓储量大,通过灵活的配置选项可实现高度密集的货物仓储,并将多个楼层连接在一起。此外,它可集成于现有的仓储系统。通过自动化,其复杂流程得以简化。在任何时候,它都能为货物的平稳供应起到缓冲作用。跨楼层仓储基于标准的Shutttle

XP垂直升降式仓储系统和Power Pick Global仓储管理软件的使用。

High-performance, flexible, and efficient storage systems like

Multi-Level Storage play a key role in mastering these challenges. The

system devised by Kardex Remstar offers a range of significant

advantages. It only needs a very small footprint, provides a very large

amount of storage volume due to its height, permits highly dense storage

of goods with flexible configuration options, and links several floors

with one another. Furthermore, it can be integrated with existing

storage systems. Italso simplifies complex processes through automation

and performs a buffering role for a smooth supply of goods at all

times.Multi-Level Storage is based on theuse of the standard Shuttle XP

vertical storage lift and Power Pick Global warehouse management

software.

多功能、多用户的仓储系统,高达38米

Multifunctional and multiuser storage systems up to 38 meters high

Shuttle XP 中的几个版本适用于跨楼层仓储。载重560 kg的卡迪斯Shuttle XP250/500

标准建造高度可达30米,完全符合现有的室内尺寸,可以在极小的占地面积内实现最大的仓储空间。载重725 kg的 Shuttle

XP700标准建造高度也可达30米,它可以扩展,减小尺寸,重新组织,或通过多种方式加以改变,具体依操作要求、位置或用途而定。载重1,000

kg的Shuttle XP1000建造高度可达20米。根据设备类型、载重和循环数,定制系统的建造高度可达38米。

Several versions of the Shuttle XP are suitable for Multi-Level

Storage.The Kardex Remstar Shuttle XP 250/500 for loads of up to 560 kg

can be built at heights of up to 30 meters as standard, fits perfectly

into the existing room dimensions, and provides maximum storage volume

on a minimal footprint.The Shuttle XP 700 for goods weighing up to 725

kg is also available at heights of up to 30 meters as standard. It can

be extended, downsized, reorganized, or adapted in any number of ways,

depending on operating requirements, location, or what it is used

for.The Shuttle XP 1000 for loads of up to1,000kg can be built up to 20

meters high.Depending on the unit type, load, and number of cycles,

customized systems can be built at heights of up to 38 meters.

用户享有的巨大优势

Extensive advantages for users

此仓储系统可以为用户提供很多益处:卡迪斯是市场上唯一一家可以建立标准高度达30米的跨楼层仓储系统的公司,如有需要,作为单独解决方案,其建造高度可达40米,因此会连接几个楼层。此外,标准配置可达六个存取口,这在市场上也是独一无二的。所有这些元素会通过跨越楼层产生更连续高效的物料流。其具有缓冲可选项、统一工作流程、优化和加速的循环和更大的吞吐量。

The user benefits of the storage system are extensive: Kardex Remstar

is the only company on the market that can build its Multi-Level

Storage up to 30 meters high as standard and, if required, up to 40

meters high as an individual solution, thereby linking several floors.

In addition, up to six access openingscan be fitted in the standard

configuration – also unique on the market. All of these elements

generate a more continuous and efficient material flow across a number

of floors, with buffering options, consolidated work processes,optimized

and accelerated cycles, and increased throughput.

连续高效的物料流和缓冲功能

More continuous and efficient material flow and buffering functions

跨楼层仓储的紧凑型设计,所占空间通常会减少40%-85%。高密度仓储和自动高度测量能够增加可用容量。该系统显著地提高了订单分拣性能,促进了无差错拣选,在生产区和仓库之间产生了直接物料流,优化了仓储空间、仓储量和库存管理。遵循“货物到人”原则,所要求的物品被自动传送至仓储系统存取口的订单拾取器,吞吐量可增加50%左右。员工走动路径更短,这意味着走动时间——整个订单挑选时间的最大部分——从65%减少到10%左右。

The compact design of Multi-Level Storage generally reduces the size

of the footprint needed by between 40 and 85 percent. Highly dense

storage and automatic height measurement increase the available

capacity.The system significantly improves order picking

performance,facilitates error-free picking, generates a direct flow of

materials between the production area and warehouse, and optimizes

storage space, storage volume,and inventory management.The requested

article is automatically conveyed to the order pickers at the storage

unit’s access opening by means of the goods-to-person principle;

throughput is increased by around 50 percent.Employees have to move

around muchless, which means that the travel time – the biggest part of

the overall order picking time – is cut from about 65 percent to around

ten percent.

快速的订单分拣,最大的精确性。

Fast order picking times and maximum accuracy

快速和有针对性地存取仓储货物,避免无效的搜索时间,显著提高吞吐量。Shuttle

XP存取口的可视化显示元件有助于快速精确的订单分拣。其准确率达99%以上,改善率达50%。Shuttle

XP的更多特点包括:可单独调节、符合人体工程学的操作员工作站;用于安全分拣的大量安全装置;可单独分隔的托盘,用于优化空间,以仓储各种尺寸货物。

Fast and targeted access to the stored goods prevents unproductive

search times, significantly increasing throughput.The visual display

elements at the access opening of the Shuttle XP help with error-free

and fast order picking.The accuracy rate is more than 99 percent, an

improvement of up to 50 percent. Further features of the Shuttle XP

include the individually adjustable, ergonomic operator work stations,

extensive safety devices for safe picking, and individually divisible

trays for optimizing the space available for storing goods of various

sizes.

适用于多种行业

Suitable for use in a wide range of industries

跨楼层仓储适用于多种行业,包括汽车、电气/电子、化工/制药、机械、维修、医院物流、医疗器械市场、仓库和配送。通过一些典型的应用实例,可以更好地说明其广泛的用途和带给用户的利益:电气批发商FEGA

&Schmitt在其海尔斯布隆中心仓库安装了两套XP 500

升降式仓储系统。它们几乎有30米高,坐落于一个专门建造的仓储塔中,其空间可容纳另外六套Shuttle XP

仓储系统。通过合并五个订单形成一个批次,员工可以毫不费力地完成订单。两套升降仓储系统大约每天分拣500个订单。自从新系统投产以来,该公司在其原有40000个小商品的基础上又增加了3000个物品;计划再增加3000个物品。

Multi-Level Storage systems are suitable for use in a wide range of

industries, including automotive,electrics/electronics, chemicals/

pharmaceuticals, machinery, maintenance,hospital logistics, the medical

device market, and warehouse &distribution.The suitability for a

wide range of uses and the diverse userbenefits can be best illustrated

by means of some typical application examples:The electrical wholesaler

FEGA &Schmitt has installed two XP 500 storage lifts at its central

warehouse in Heilsbronn. They are almost 30 meters high and housed in a

specially built storage tower that has space for a further six Shuttle

XP units. By combining five orders to form a batch, the employees can

make the orders ready for shipping with very little effort. Around 500

orders are picked every day from both storage lifts. Since the new

system was commissioned, the company has already been able to add

another 3,000 items to its range of 40,000 small products; there are

plans for another 3,000 items.

812平方米的仓储空间,占地面积仅为40平方米。

812 m² of storage space on a footprint measuring just 40 m²

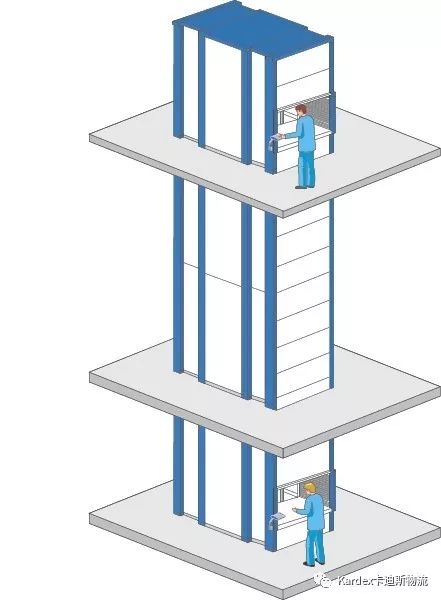

一个有关自动仓储系统的案例是卡迪斯为制造商菲尼克斯电气提供了解决方案,利用较小的占地面积实现最大的仓储空间:四套10.45米高的

ShuttleXPmultiple

系统集成于现有仓库,仓储空间约为812平方米,跨越两层楼,占地面积尚不足40平方米。该设备在两层楼接近生产区的地方都设有存取口,用于仓储和检索货物。ShuttleXpmultiple

系统含有两个背对背的模块化仓储设备,特别适用于安装在建筑物内行走不便的区域,如角落、壁龛。当操作人员在存取口分拣货物时,系统会在后台检索新的托盘,这些并行处理提高了吞吐量。

One example of automatic storage systems that provide maximum storage

space on a small footprint is the solution supplied by Kardex Remstar

for the manufacturer Phoenix Contact Electronics:Four 10.45-meter-high

Shuttle XPmultiple units with around 812 m2 of storage space were

integrated into an existing warehouse across two floors on a footprint

measuring just less than 40 m². The units have access openings on both

floors for storing away goods and retrieving them close to the

production area.The Shuttle XPmultiple system, which consists of two

modular storage units arranged behind one another, is particularly

suitable for installing indifficult areas of a building, such as corners

and niches. While the operator picks the goods atthe access opening, a

new tray can be retrieved from the rear section. These parallel

processes increase the throughput.

来源:卡迪斯物流